Potential

Our aim is to develop autonomous robotic solutions to improve the safety, efficiency, and sustainability of industrial work. This robotics technology for industrial inspection and maintenance has the potential to scale up and benefit industrial sites in the energy, oil and gas, industrial processing, mining, and construction sectors world-wide.

News

Key Figures

2016–19

Wyss Zurich period

150+

Team size

Wyss Zurich period

Team size

Project Description

Our aim is to develop autonomous robotic solutions to improve the safety, efficiency, and sustainability of industrial work. This robotics technology for industrial inspection and maintenance has the potential to scale up and benefit industrial sites in the energy, oil and gas, industrial processing, mining, and construction sectors world-wide.

Industrial operations still rely on the continuous physical presence of humans despite a shortage of qualified workers, productivity limitations, and persistent workplace accidents. In the EU alone, there will be a shortage of 1.5 million plant operators by 2030 owing to retirement. Furthermore, plant downtime accounts for $270 billion in productivity losses annually caused by unplanned shutdowns. In contrast to machines, which are able to detect early indications of problems in heat and vibration patterns, human senses and cognition are often incapable of recognizing problems at an early stage, and human error remains the primary cause of workplace accidents that too often lead to devastating damage to humans and the environment.

The next generation of AI-powered, agile robots will make it possible to transition from human-centric to autonomous operation. With this technology, plant operators can automate repetitive inspection and maintenance tasks and avoid exposing their staff to unpleasant and potentially dangerous environments. Equipped with sensitive sensors, robotic co-workers provide reliable and accurate insights into the health of equipment and infrastructure to maximize plant availability. Compared with fixed installed devices, a mobile sensing platform provides complete coverage of an entire plant, making it possible to detect problems beyond the capabilities of stationary sensors.

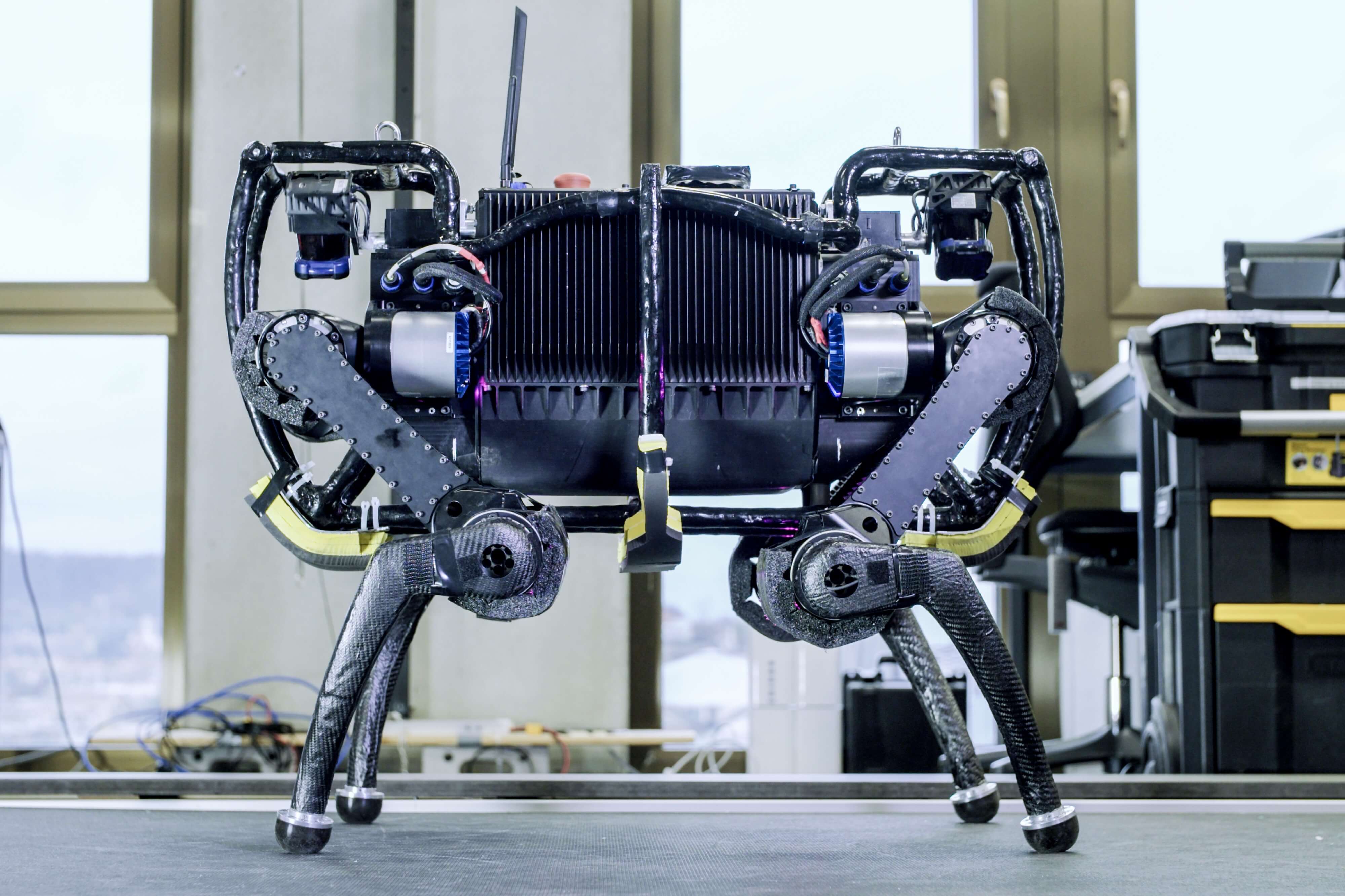

ANYbotics AG offers the world's most advanced robotic inspection solutions through two distinct platforms: ANYmal, an industrial-grade, safety-certified autonomous robot, and ANYmal X, the world's only legged robot with Ex certification for all oil and gas and chemical applications.

Contact

ANYbotics AG

info@anybotics.com

Faculty Mentor

Marco Hutter

Faculty Mentor

Roland Siegwart

Partners and Funding

Project Partners

- ETH Zurich, Robotics Systems Lab

Funding Partners

- EU Horizon 2020

- Eurostars/Eureka

- Gebert Rüf Foundation

- Innosuisse

Project Partners

- ETH Zurich, Robotics Systems Lab

Funding Partners

- EU Horizon 2020

- Eurostars/Eureka

- Gebert Rüf Foundation

- Innosuisse

Achievements

Founding Team

Péter Fankhauser

Co-Founder

Hanspeter Fässler

Co-Founder

Christian Gehring

Co-Founder

Marco Hutter

Co-Founder

Andreas Lauber

Co-Founder